Weaving sakiori is a slow process. The old textiles need to be selected and prepared, cut into strips, the loom warped and any patterning decided upon. After all of this, the actual weaving can take place, and often takes less time than the preparations did. On the other hand, Japanese weavers making sakiori back in the late 19th and early to mid-20th centuries felt that it was fast work. The hemp or other bast fibers only had to be prepared and spun in sufficient quantities for the warp and part of the weft, instead of for the whole piece of cloth. The cotton rag was easy to tear or cut into small strips and the weaving went faster because the thick rag weft picks took up more space than a strand of bast fiber yarn, allowing the weaver to cover more warp length per pick.

In today’s world, no one need make sakiori at all. New textiles are produced and transported so quickly and cheaply that everyone has access to clothing, even if they are cast-off garments. Hand weaving and making clothing are done almost exclusively by choice, as hobbies or as artistic expressions. People can pick and choose which parts of a textile they want to spend time making by hand. Some people still enjoy starting from the beginning, readying the raw material for spinning, spinning the fiber, perhaps dyeing it, weaving it into cloth and then sewing it into the final product. But most people choose to do one or two of the steps themselves and use ready-made materials that they can purchase. Most knitters and weavers buy yarn already spun. Even rag rug weavers often buy new fabric to make their rugs, because the large rectangles of yardage are easy to tear into long strips to make the weaving go faster.

Obviously my preference is to recycle used textiles as rag instead of using new materials, but I will be the first to admit that this makes the rag preparation take quite a bit longer. As I prepare to teach my first Western Sakiori Scarf class at the Mannings next month, I have been thinking about how other weavers will feel about the work involved in rag preparation. I have taken a lot of weaving classes and I know from experience that not all weavers are created equal. Some weavers enjoy the enforced quietude and slowness of preparing to weave and weaving. Conversely, some people are drawn to weaving for the very reason that it is a relatively fast way to make cloth (as opposed to knitting or crocheting), and they like the quick throw-and-beat of consistent weft threads wound on bobbins and carried by a shuttle. Some weavers dislike the steps of warping the loom and want to get to weaving as quickly as possible, not spend even more time preparing weft material. Even among weavers who are interested in learning about sakiori weaving, there will be some of this variation.

My class will be using pre-warped looms, so that we can enjoy more weaving time and everyone can get the most out of their weekend. Serendipitously, the staff at the Mannings approached me with a new yarn one of their suppliers had started offering. The yarn is Silk Chiffon Ribbon Yarn by Himalaya Yarns and consists of strips of recycled (!) silk fabric knotted or stitched together in random color order to make a continuous skein of yarn. It is made in Nepal as a cottage industry. I brought home a skein to make a sample prior to my class:

All of the skeins are different. The skeins I had to choose from that day were all composed of a gauzy, chiffon-style silk that was not smooth or shiny. The strips were sewn together or sometimes knotted:

The first thing I did was to wind the yarn off by color:

Then I wove it as it came from the skein, varying the colors and incorporating the stitch lines and some of the knots as I came across them. The strips are wider than what I normally use in sakiori. Also, I normally lay each strip in individually, overlapping it with the preceding strip, so there are no lumps or visible stitches. The fabric (left, below) was therefore a bit different than my usual (right, below).

It is somewhat thicker and heavier than what I usually make, but upon wet finishing, I found that it did drape well and wasn’t too heavy for a scarf, though I feel it would do better as a table runner or fabric for a bag.

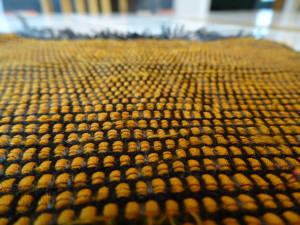

I took it out to the Mannings for them to use as a sample with the yarn for sale, and while some of the staff were trying it on, discovered that some people found it somewhat rough-feeling against the skin of the neck. Obviously that will bother some more than others, but I wandered back to the yarn bin, hoping for some better choices. I felt that the problem lay not in the strip width or the knots but rather in the gauze weave structure. Below you can contrast the coarser, matte texture of the yarn with the smooth, shiny texture of the thinner silk rag I normally use:

I found that the skeins varied wildly, but there were some that were composed of all or mostly smoothly-woven silks as opposed to the gauzy chiffon. I took home one of those skeins to see if it came out better.

You can see in the close-up that the texture is much more like the silk rag than the gauzy chiffon. The strips are still wider, but upon weaving it up, I found that, while it is a bit heavier than what I make with silk rag, it came out much softer and had better drape than the gauze. In fact, other than the weight, it is just like what I normally make.

I still believe that thinner strips of softer silk make better cloth, but using the smoother recycled yarn gives results that are nearly as good and will allow some weavers to enjoy the process more. For anyone reading who is signed up for the Mannings class, they have requested more of the smoother type of yarn if Himalaya Yarns has it available.